UV disinfection has emerged as a notably efficacious substitute for pasteurization in managing Listeria within dairy facilities. The technology's merits, including energy efficiency, compact equipment design, and increased pasteurizer accessibility for production, have propelled its widespread adoption. Although pasteurization remains the benchmark for water treatment, the FDA has recognized UV disinfection as an equivalent method to pasteurization.

Listeria is a serious public health concern, and food industry professionals are always looking for ways to control and eliminate it in food processing environments. In this article, we will explore one of the most efficient methods of controlling Listeria: ultraviolet (UV) disinfection. We will also discuss how UV treatment compares to the process of pasteurization, which has long been the gold standard for water treatment in the dairy industry.

UV disinfection is when water is exposed to UV rays to eliminate harmful pathogens like Listeria. Studies have shown that conveyor belts treated with UV exhibit a significant decrease in the population of Listeria. Inline UV treatment has also been proven effective in the brine chiller system used to process certain foods.

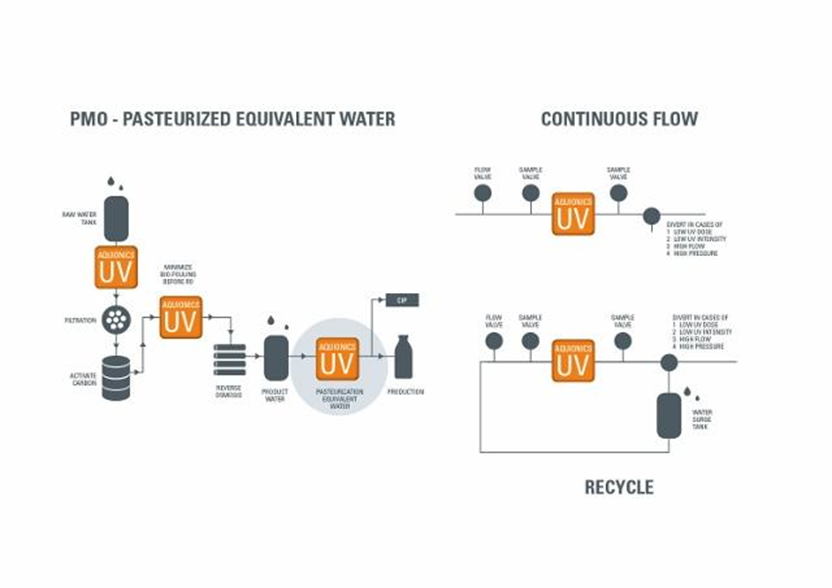

In 2019, the FDA published a revised Pasteurized Milk Ordinance (PMO), which presented UV disinfection technology as an approved alternative to pasteurization for water treatment in dairy plants. However, when a new technology comes along in an industry, questions arise: How does the technology work? How will it affect the production process? Is it equivalent to or better than the current gold standard? These concerns are natural, especially since UV disinfection and pasteurization are so different.

In 2004, the National Advisory Committee on Microbiological Criteria for Foods (NACMCF) defined the parameters for evaluating how different technologies could be equivalent to pasteurization. Pasteurization is a process that reduces the most resistant microorganisms of public health significance to a level that does not pose a public health risk under normal distribution and storage conditions.

To determine if UV disinfection is equivalent to pasteurization for water treatment, the FDA PMO evaluated the effectiveness of the two technologies in disinfecting E. coli, Listeria, Clostridium, Pseudomonas, and Streptococcus. In dairy applications, the highest concern is organisms that can grow in refrigerated temperatures where liquid temperatures are maintained. HTST (High Temperature/Short Time) pasteurization provides a 5-log reduction of these organisms. For an alternative technology to be deemed equivalent, it must provide the same level of performance in disinfecting the same pathogens.

The FDA has established that medium-pressure UV technology must have a dose of 120mJ/cm2 to be equivalent to pasteurization. This dose is higher than for a 5-log reduction of common dairy contaminants (40mJ/cm2). Still, it is necessary because some viruses, like Adenovirus, are more UV-resistant. A 120mJ/cm2 dose ensures adequate virus inactivation.

Since 2009, many dairy facilities have started using UV disinfection for water treatment due to several benefits, including:

UV technology and pasteurization have been extensively studied and compared. While neither method provides sterile water, UV disinfection has an additional advantage. Psychrotrophic bacteria, such as Pseudomonas fluorescens and Pseudomonas fragi, can survive pasteurization and cause spoilage by producing heat-stable, proteolytic, and lipolytic extracellular enzymes. UV disinfection that provides a dose of 120mJ/cm2 can quickly achieve a 5-log inactivation of these organisms.

UV disinfection has proven to be a highly effective alternative to pasteurization for controlling Listeria in dairy facilities. Many facilities widely use this technology due to its advantages, which include saving energy, having a smaller equipment footprint, and increasing the availability of the pasteurizer for production. The FDA has deemed UV disinfection equivalent to pasteurization, which remains the gold standard for water treatment.

Read more information on the NACMCF’s work on determining pasteurization equivalence at:

Share: