To scientifically validate the effectiveness of UV-based air disinfection in an air cooler, the Fraunhofer Institute for Process Engineering and Packaging conducted a series of tests in cooperation with the heat exchanger manufacturer thermofin and Nuvonic.

UV-C radiation is a highly effective tool for combating harmful bacteria, pathogenic germs, yeasts, and mold spores. UV-C can efficiently deactivate up to 99.9% of microorganisms, making it a suitable disinfection technology for any area of the food industry. The targeted use of the technology can minimize the risk of contamination and increase the standard of hygiene even in the most demanding areas of the food processing industry, such as production rooms, cold storage, warehouses, and high-risk packaging areas.

In addition to improved hygiene, there is also a significant economic advantage.

A large savings potential arises from extended cleaning intervals and lower personnel expenses. The use of cost-intensive chemicals is significantly reduced.

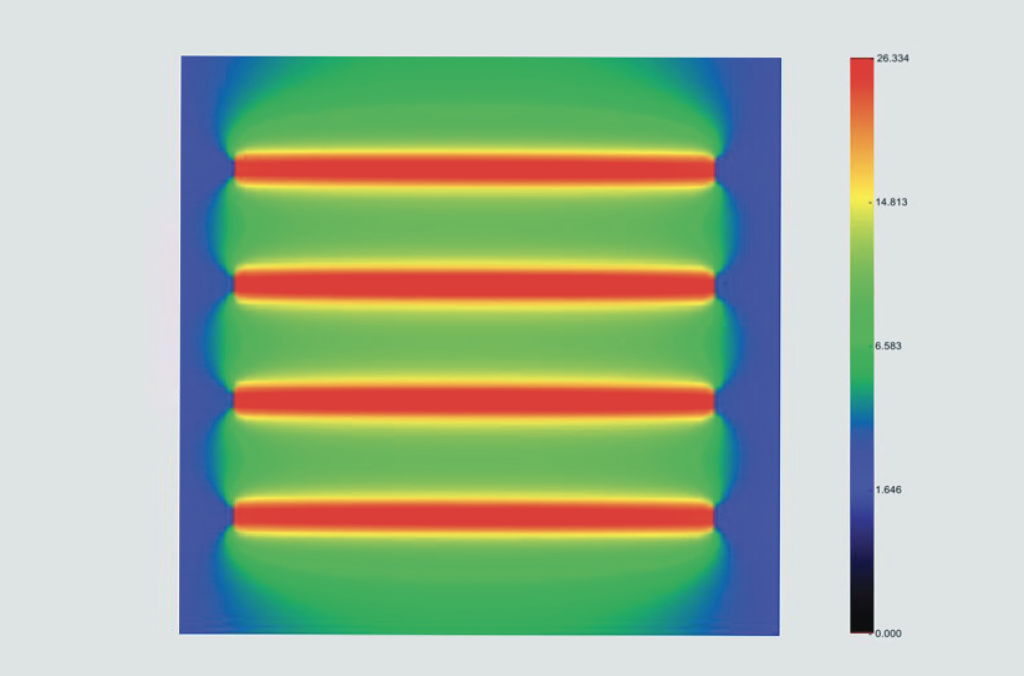

As an installation in evaporators and air coolers, UV-C also ensures lower energy consumption. Cooling leads to condensation on the cooling fins, where suspended solids and microorganisms from production are deposited. The result is biofilms that reduce the cooling load and release germs into the production air. When the UV-C devices are mounted directly in front of or behind the cooling fins of the air cooler, the UV-C radiation prevents the formation of biofilms, and the cooling load of the evaporator remains constant.

Due to their shatterproof design, UVpro disinfection units for use in the food processing industry, are IFS and HACCP-compliant.

Up to 99.9 % germ reduction.

To scientifically validate the effectiveness of UV-based air disinfection in an air cooler, the Fraunhofer Institute for Process Engineering and Packaging conducted a series of tests in cooperation with the heat exchanger manufacturer Thermofin and Nuvonic.

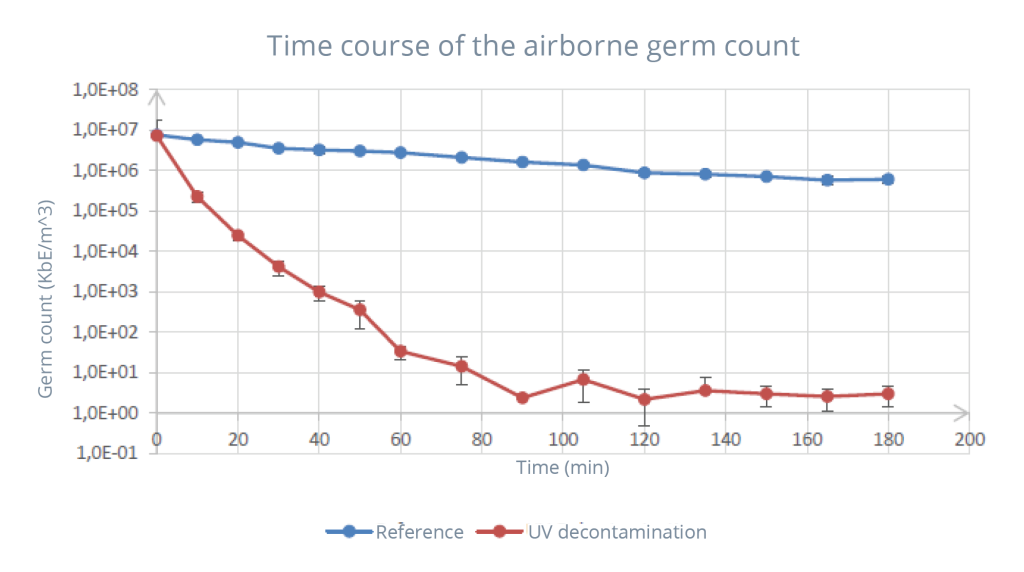

We conducted a microbiological investigation on a Thermofin air cooler that had four integrated UVpro disinfection devices. We examined the impact of the UVC device on the concentration of Bacillus subtilis DSM 4181 spores in the air over time, in comparison to a room that did not have a UVC device.

The diagram illustrates the results of the study. The disinfection unit installed in the air cooler shows a significant reduction of 99% in germ content compared to the control group without UV-C, after only 20 minutes. Within less than 40 minutes, the test room effectively removed over 99.9% of the initial germ concentration.

The overall result of the installation is very positive. The water has not detected any germs since commissioning. We have completely eliminated the use of chemicals, which cost around €7,000 per year.

Considering the life cycle of a UVC tube and the associated costs of a tube replacement after 12,000 operating hours, approx. 5,600 € can be saved annually. The system pays for itself after about 1.5 – 2 years.

Improved air hygiene during ongoing production.

The formerly problematic air cooler turns into a disinfection device.

For the complete test report, please contact germany@nuvonicuv.com

Share: