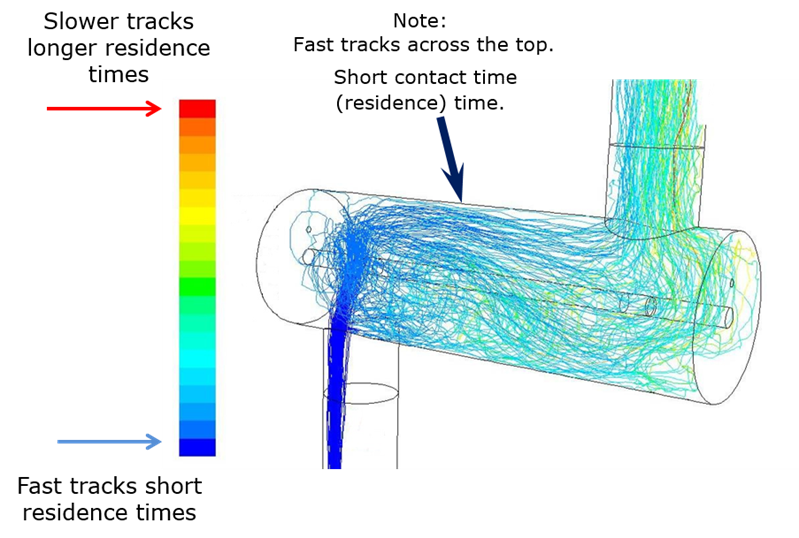

When selecting a UV water treatment system, the water process flow is one of the most important factors to consider. The flow rate determines the amount of water treated in a given period. It ensures that the necessary amount of UV light treats the water for effective purification. However, an additional flow rate could occur when implementing a medium-pressure UV system in an industrial environment.

Medium-pressure UV lamps produce heat that can significantly affect the industrial process. Close monitoring of the heat is necessary as the UV system could overheat, which can lead to system shutdown and interruption of the water treatment process. As a result, the amount of treated water available for use in production or the final product could reduce. Therefore, when considering a medium-pressure UV system, it is vital to monitor the flow rate of the water.

One of the first questions is whether the treated water comes in a batch production process, where water is necessary on demand, or whether the water flow is continuous while in production. It is critical to determine this aspect, as the type of production process will affect the water flow rate. Suppose the treated water is part of a batch production process. In that case, the frequency of stops between batches and the duration of flow interruptions are essential. This information is crucial for determining the flow rate, as the UV system will have to adapt to breaks in the water flow.

In addition, it is essential to determine whether the water is in an open or closed-loop production process as it will influence the flow rate, as the water will flow differently in each type of system. For example, a continuous flow open loop production process requires a flow rate of 2 per kW of UV lamp power to dissipate heat in the water treatment process. Assuming the facility has a continuous flow open loop production process, a minimum flow rate of 20 gpm (2 x 10 kW) is needed to prevent overheating of the UV system.

If a facility uses a batch water treatment procedure that temporarily stops water flow through the UV system, a closed loop recirculation line may be necessary. The exact minimum flow must be calculated in such cases, but additional factors should also be considered. The total volume of water in the closed loop and the length of the flow interruption are critical factors. For instance, if the lamp’s power output were one kilowatt-hour, it would take at least 13 liters of water to run (kWh). Therefore, if the water flow must stop for two hours with a UV system with a 10 kW output power, the total volume in the closed loop must be at least 260 gallons (13 x 10 kW x 2 hours).

However, not all facilities can install a recirculation loop in their process line due to limited budgets or physical space. In such cases, bleeding water from the UV system and redirecting it to either drain or for reuse in another process may be a more feasible option. Nevertheless, before constructing a new UV system, it is imperative to understand these flow calculations.

Manufacturers are concerned about plant shutdowns due to insufficient heat dissipation from UV lamps with medium pressure. Therefore, it is crucial to consider other water flow characteristics besides the “gallons per minute” rate to guarantee safe operation and an adequate supply of treated water for production. In conclusion, when implementing a medium-pressure UV system in an industrial setting, careful consideration of the flow rate of the water is essential to ensure effective purification.

Share: