Most new breweries are connected to a municipal water supply system where the water has been chlorinated.

With the rapid expansion of new craft breweries across the country, it’s not surprising to see many of them take a ‘minimalist’ approach to water treatment to keep initial capital costs down.

Water is a crucial ingredient in the brewing process, and it is essential to ensure that the water is of high quality to produce quality beer. However, many craft breweries need more money or resources to invest in expensive water treatment systems. In response, these breweries have opted for a more cost-effective approach that still meets the standards for producing quality beer.

Many new breweries are tapping into the municipal water supply systems, which usually chlorinate the water. To remove the chlorine, they use granular activated carbon (GAC). Some breweries modify the water’s chemistry before mashing, while others use dechlorinated water. This helps in extracting the sugars from the grains.

It is a common misconception among brewers that boiling the wort and using chlorinated water provide immunity against microbial contamination. However, it is well established that some microorganisms resist chlorine and can thrive in suitable conditions with the proper nutrients. This highlights the importance of taking additional measures to ensure the safety and quality of the final product.

Using GAC can lead to downstream contamination as it can provide a breeding ground for harmful organisms. Moreover, thermophiles and some chlorine-resistant microorganisms can survive boiling and cause wort contamination if there is no treatment before the mashing process. The Institute of Brewing published an article that sheds light on the common Enterobacteriaceae found in the wort, including Citrobacter, Enterobacter, and Klebsiella. These organisms can slow the fermentation process and alter the pH, leading to inconsistencies in beer flavor and taste, particularly regarding fuel alcohols, esters, sulfur compounds, carbonyl compounds, and volatile phenols.

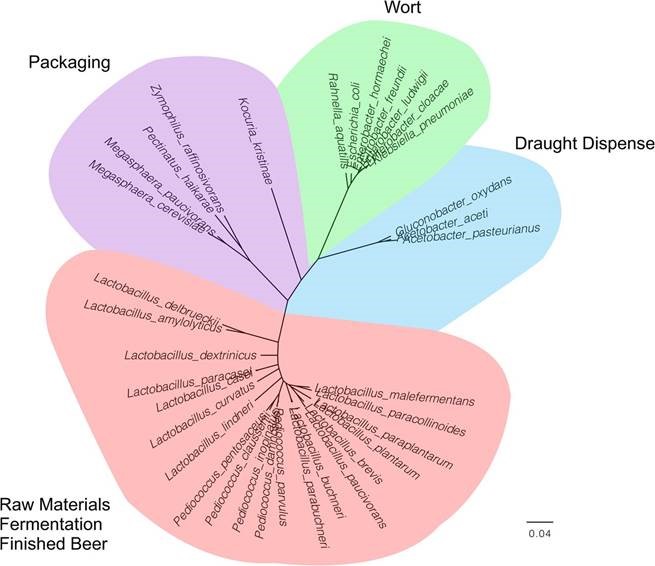

The Microbiology of Malting and Brewing goes into greater detail and highlights the potential dangers of Bacillus and Clostridium in the mash or wort, which can cause excessive acidification, nitrosamine formation, or contribute to butyric acid production. Addressing contamination issues before mashing can enhance filterability and extraction efficiency, and common microorganisms at various stages in the brewing process include:

Several brewers have begun using UV purification systems after GAC beds to combat microbiological pollutants like chlorine-resistant organisms, thermophiles, and other unwanted species that flourish there.

Organoleptic evaluation and sensory examination can suffice in identifying the specific contaminants causing problems with quality and consistency since many microbial contaminants can produce distinct flavor and aroma issues. Implementing a UV system to make the appropriate UV dose after detecting the organisms in the mashing process water can mitigate the risk of contamination.

Share: